A few years ago, I converted my SUV to a camper by building a platform bed in my 2009 Honda CR-V. It’s still a super popular post on this blog– see the original post here. Every so often, folks reach out to me with their own stories and how-to’s on how they converted their car or SUV, so I decided to start featuring them… and they’re even better than my original post!

Here’s Nicole Aichele on converting her Subaru Outback into a camper. All photos courtesy of Nicole.

After a year of health issues leaving me unable to camp, hike, or do many of the outside activities I love, I became deeply depressed and frustrated about my future. As I slowly regained my mental and physical strength, I found both a new gratitude for my health and a new determination to set my old dreams into motion… one of those dreams is to car-camp the entire western US.

After many months of researching, planning, and saving, I finally set the wheels in motion (literally) this past June. Here’s how I did it.

DECIDING ON DESIGN

Ideally, the design of your bed set up should reflect your own personal needs and preferences.

I also will say that if I can leave people with one thing when it comes to building a bed in your car, or really building anything, it’s the importance of taking good measurements. As my dad says: “Measure twice, cut once.”

The first thing to figure out is how long you want your bed. Having a long bed (6’2) was a top priority for my boyfriend and I because we are tall…but everyone is different. If a bed can fit without pushing the front seats forward that’s great, but in our Subaru Outback it would be impossible to have the length we wanted without having the front seats forward.

We also chose not to remove the seats since the car is new and we didn’t want to risk ruining it, and found it unnecessary anyway.

The second thing to determine is the width you want your bed. For us this meant measuring wheel-well to wheel-well. We made the bed platform flush with the top of the wheel well, so in reality there is a bit more space (roughly 5’’ on each side) beyond the platform. In total we have about 51” of space (almost exactly the width of a double bed) which snuggly fits our two large single Therm-a-Rest Mondo King mattresses, side by side.

The third element of the design is determining the height. We wanted to raise our bed as minimal as possible in order to avoid being completely cramped against the ceiling while sleeping, but still allowing for storage underneath. Raising the platform to 6” fits the under the bed storage containers, but also leaves room to have our legs up while sitting in bed, (just over 2 ft. at the tallest point and just under 2 ft. at the lowest).

The last thing to determine about your design is whether or not you want the bed platform to be foldable. We had no choice but to make ours foldable because we couldn’t keep the bed straight and drive at the same time, because the seats are completely forward.

THE BUILDING PROCESS

Supplies:

- ¾” plywood, 42” wide x 74” long $33.00

- Wood Glue $8.00

- 2 Heavy duty hinges $16.00

- Nuts, bolts, large washers, lock washers $15.00

- Outdoor utility rug $20.00

- Multi- floor adhesive $5.00

- Legs (two 2x2s) $20.00

- Pins and Brackets $5.00

- U Bolts $6.00

Total: (NOT including our mattress) $128.00

For wood we used a ¾” piece of plywood that was over 74” long. The pros of using ¾” plywood is that it’s sturdy and can hold 2 adults without bowing, and also very easy to work with. However, it’s heavy and can be cumbersome, so if you’re making a bed for one, definitely not as necessary.

We had the wood ripped (cut) to fit the width we had previously determined to be 42” (distance from wheel-well to wheel-well) to simplify all the construction at home. However even so, we completed a lot of additional cutting and drilling at home, because we have the equipment. If you don’t have access to a skill saw or other tools, then you’ll have to go back and forth to the hardware store, which is not uncommon. Some hardware stores even let you rent tools.

Step 1: Construction of the box platform

The box component is 42” wide x 36” long x 6” tall and has 3 sides. It purposefully takes up the entire back area of our car before the seats start (which is also where a slant starts). It maximizes storage and sturdiness while remaining level. Building the box was straightforward: we cut wood for the 3 sides, (2 sides are the same and are 6” tall x 35 ¼” long, and then there is a back piece which is 6” tall x 42” wide). We then glued the wood pieces to the 36” plywood piece and screwed them for ultimate stability.

Step 2: Construction of the hinged component

The hinged component is two pieces of 19” long x 42” wide plywood, hinged together. When hinged together the piece measures 38” long in total (38” plus the 36” of the platform box is 6’2”). We offset the hinge, in order for this component to be weight bearing. If the hinge is not offset, it would literally bend in half the moment enough weight was applied and would not work as a bed. In addition to offsetting the hinge, we reinforced it with oversized washers and lock washers along with the nuts and bolts. It’s important to note, the hinged component rests on a ledge that we attached to the box platform. We attached a 3” x 42” strip of the plywood, ¾” down from the top of the platform, on the back edge of the box.

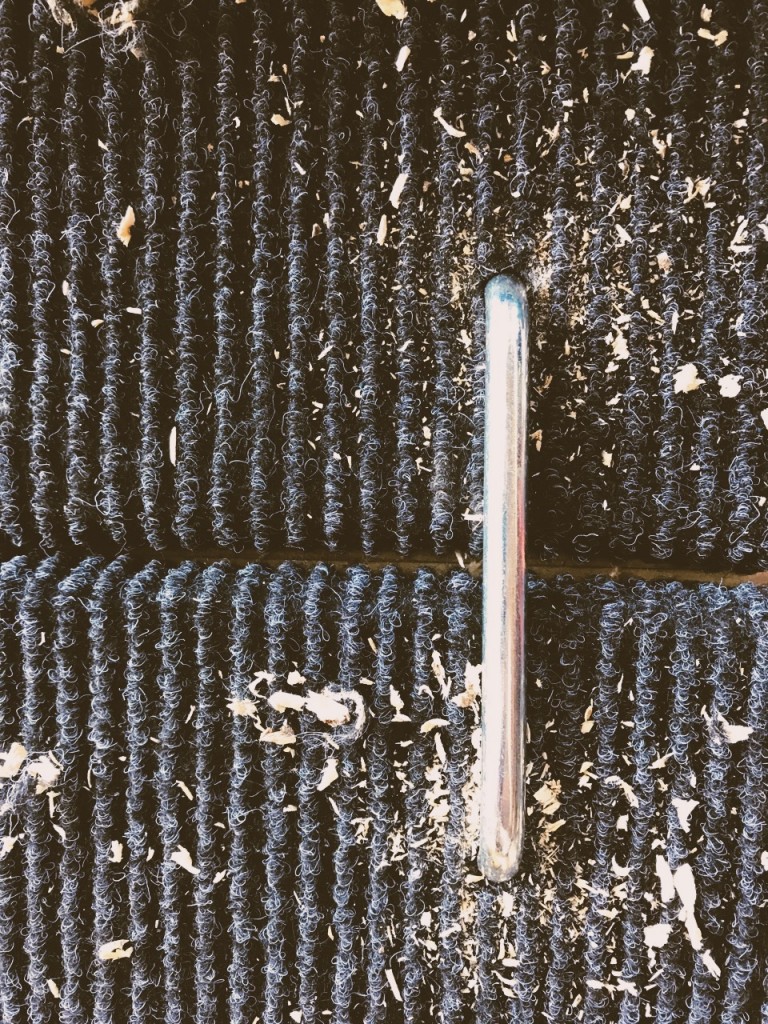

Step 3: Applying the carpeting

The main reason we wanted to carpet the entire bed is to eliminate having splinters of wood all over the car, our pillows, and our foam mattress. We didn’t use fancy outdoor carpet, instead we found a multi-purpose outdoor utility rug for $20 at the hardware store and used a razor blade to trim it at home. We glued the carpet using “general use multi-floor adhesive” on the main faces of the wood (although I don’t know how necessary the glue really is) and then we wrapped the carpet around and tacked it securely underneath. Folding the carpet completely underneath the base component is aesthetically pleasing, and also adds a tiny bit of height to the storage area.

Step 4: Attaching of the legs

The legs serve as the main support for the hinge component, which supports our heads… so it was really important we made them sturdy and stable. We used two 2x2s and cut them to fit securely underneath the hinged component at 26” tall. They’re attached by a pin, to a bracket on the underside of the wood of the hinged component. We had to drill a custom sized hole through the brackets in order to fit the pins. The pins and brackets are awesome for easy removal, while also making it possible for the legs to pitch slightly forward for some added resistance to bending.

Step 5: Installation of the U-bolts

To secure the box platform to the hinged component we used two 4” U-bolts. We drilled a hole on each side, one through the box platform and one through the hinged component (through both the carpet and wood), 2 ½” from the edge. The U-bolts are then dropped into the holes in order to secure the two components together while sleeping. The U-bolts come out easily when folding the bed platform up in the morning.

I hope this guide encourages other people to be less intimidated by the idea of building a bed in their car, especially women. As I write this from a campground in the middle of nowhere in Utah, I can assure you it’s worth it.

Also, a big thank you to my boyfriend who traded in his car for this Subaru and then let me build a bed in it…and to Erin for supporting me these past months and giving me the tools to take on risks and adventures like this one.

I’m Nicole. I currently write, photograph, and live out of the back of a Subaru Outback with my boyfriend. Although I’m only on the road for summer, I’m always looking for rad adventures and new opportunities in the outdoor industry.

I’m Nicole. I currently write, photograph, and live out of the back of a Subaru Outback with my boyfriend. Although I’m only on the road for summer, I’m always looking for rad adventures and new opportunities in the outdoor industry.

Follow Nicole’s adventures on Instagram at @nicole_aichele, and comment here or DM her for any questions on this conversion or her trip!

Please ignore this text box - Recoleta Font

Nice plan for the Outback. Thanks I camp in mine on the 60 as plug side by adding a 20 x 30inch plywood behind the passenger side with the seat upright pushed forward. Works for me under 6 feet